Engine Maintenance Tips

Engine Maintenance Tips

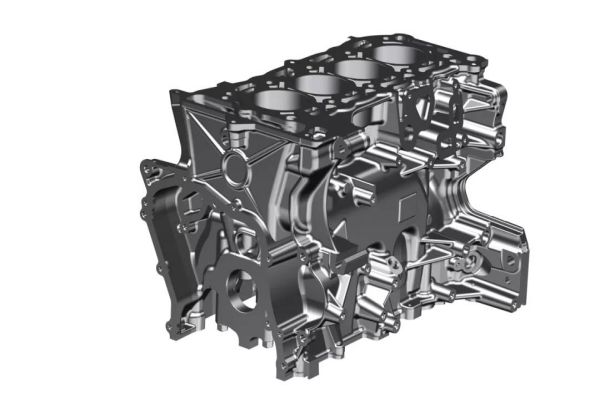

Next, we will introduce the basic knowledge and maintenance knowledge of bus engines.

Summer maintenance, cleaning first!

Faced with urban congestion and road conditions, my bus has to start and stop frequently. In addition, the continuous use of air conditioning in summer puts greater pressure on the engine, which can easily generate sludge and cause engine damage. At this point, you need a lubricating oil with powerful cleaning functions, and of course, Shell's extraordinary Heineken! It has a unique power cleaning and dispersion factor, which quickly removes busbon particles and keeps them in a suspended state. It will not attach to engine components again and will be completely removed during the next oil change to avoid any harm to your bus.

Thermometer, check frequently!

If the temperature gauge shows that the bus engine often operates at abnormal temperatures, the engine will face significant pressure and may be damaged as a result. For example, if a bus frequently travels short distances, less than 10 kilometers, and the engine does not heat up enough, it is easy to produce sludge and busbon deposits. At this point, you should give your beloved bus Shell's extraordinary Heineken lubricant, which has a unique power cleaning and dispersion factor, cleaning the engine and maintaining normal engine pressure, making driving feel smooth and perfect at all times!

Lubricating oil, coolant - don't forget!

To ensure smooth operation of bus engines, lubricating oil and coolant are essential. Ignoring these two aspects often results in permanent damage to the engine. So, according to the recommended usage and replacement cycle in the bus user manual, it is very important to replace the lubricating oil and coolant correctly for the maintenance of your bus!

Related Products

.jpg)