What is a Commercial Vehicle Air Filter Assembly?

A commercial vehicle air filter assembly is a crucial component in the air intake system of a bus engine. Its primary function is to filter the air entering the engine, preventing dust, sand, and other impurities from infiltrating the engine's internal components. By doing so, it ensures the engine operates smoothly and efficiently, thereby extending its lifespan and maintaining optimal performance.

The air filter assembly typically consists of two main parts: the air filter element and the air filter housing. The air filter element is the core component responsible for filtering the air. It is usually made of paper or synthetic fibers, which are capable of trapping tiny particles and impurities present in the air. The air filter housing, on the other hand, serves to protect the filter element and secure the entire air filter assembly in place. It is commonly constructed from durable materials such as plastic or metal.

(1).png)

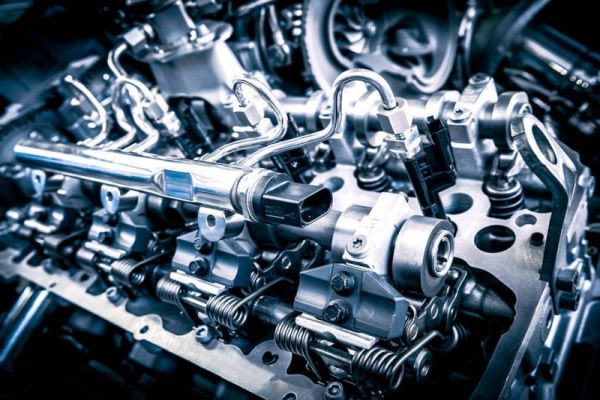

Importance of Air Filter Assembly in Commercial Vehicles

The air filter assembly plays a vital role in maintaining the health of a commercial vehicle's engine. In environments where vehicles are exposed to high levels of dust, dirt, and other airborne contaminants, the air filter becomes even more critical. Without a properly functioning air filter, these contaminants can enter the engine, leading to increased wear and tear, reduced engine efficiency, and potentially costly repairs.

For commercial vehicles like buses, which often operate in urban or off-road conditions, the air filter assembly must be robust and reliable. Buses frequently travel through areas with high levels of pollution, construction sites, or unpaved roads, all of which can expose the engine to harmful particles. A high-quality air filter assembly ensures that the engine is protected from these external elements, allowing it to perform at its best.

(1).png)

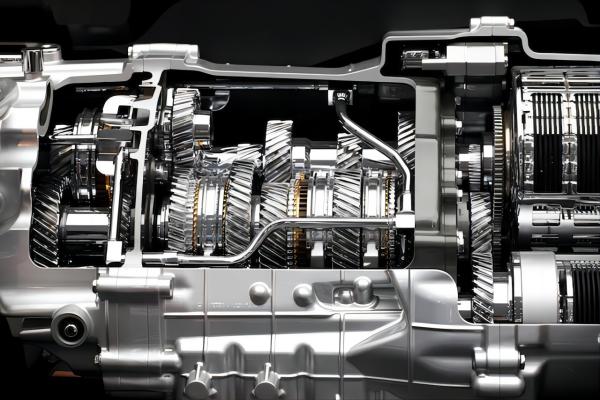

Components of an Air Filter Assembly

1.Air Filter Element: This is the heart of the air filter assembly. It is designed to capture and retain particles as small as a few microns in size. The material used in the filter element is crucial, as it determines the filter's efficiency and durability. Paper filters are common due to their cost-effectiveness and ability to trap small particles. However, synthetic fiber filters are gaining popularity because of their superior filtration capabilities and longer lifespan.

2.Air Filter Housing: The housing is the outer shell that encases the filter element. It is designed to withstand the rigors of daily use, including exposure to heat, moisture, and mechanical stress. The housing must also provide a secure fit to prevent unfiltered air from bypassing the filter element and entering the engine. Materials like high-strength plastics and metals are commonly used for housing construction, ensuring durability and longevity.

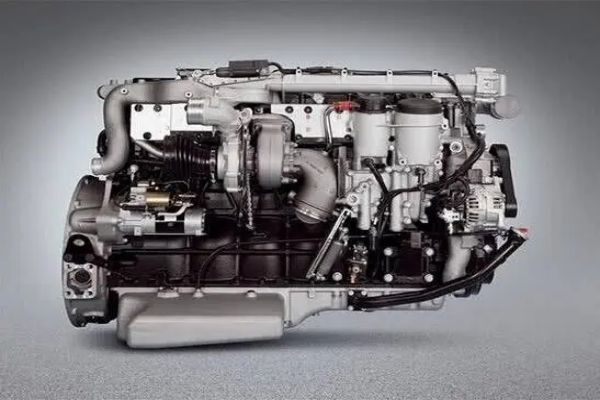

Maintenance and Replacement

Over time, as the vehicle is driven, the air filter element accumulates dust and debris. This buildup can restrict airflow, reducing the engine's efficiency and increasing fuel consumption. In severe cases, a clogged air filter can lead to engine misfires, reduced power output, and even engine damage. Therefore, regular maintenance and timely replacement of the air filter element are essential.

The frequency of air filter replacement depends on several factors, including the operating environment, the type of vehicle, and the manufacturer's recommendations. For commercial vehicles operating in harsh conditions, such as buses in dusty or polluted areas, the air filter may need to be replaced more frequently than those in cleaner environments.

When replacing the air filter, it is crucial to choose the correct filter for the specific vehicle model and engine type. Using an incompatible filter can lead to improper filtration, reduced engine performance, and potential damage. Many manufacturers provide detailed guidelines on the appropriate air filter specifications for their vehicles, ensuring that the replacement process is straightforward and effective.

(1).png)

Choosing the Right Air Filter Assembly

Selecting the right air filter assembly for a commercial vehicle involves considering several factors:

1.Vehicle Specifications: Different vehicles have different air filter requirements based on their engine size, design, and operating conditions. It is essential to choose a filter that matches the vehicle's specifications to ensure optimal performance.

2.Filtration Efficiency: The filter's ability to trap particles of various sizes is a critical factor. High-efficiency filters can capture smaller particles, providing better protection for the engine.

3.Durability: The filter should be able to withstand the operating conditions of the vehicle, including exposure to heat, moisture, and mechanical stress. Durable filters last longer and require less frequent replacement, reducing maintenance costs.

4.Brand and Quality: Opting for reputable brands and high-quality filters can make a significant difference in performance and longevity. While these filters may be more expensive upfront, they often provide better value in the long run by reducing the risk of engine damage and improving fuel efficiency.

In summary, the commercial vehicle air filter assembly is an indispensable component of the engine's air intake system. It ensures that the engine receives clean air, free from harmful contaminants, thereby maintaining its performance and longevity. Regular maintenance and timely replacement of the air filter element are essential practices for any commercial vehicle operator, particularly those operating in challenging environments.

By understanding the importance of the air filter assembly and choosing the right components for their vehicles, operators can ensure that their engines remain in peak condition, reducing the risk of costly repairs and downtime. Whether it's a bus navigating city streets or a truck traversing rugged terrains, a reliable air filter assembly is key to keeping the engine running smoothly and efficiently.

Related Products

Related News

-

Shifting Gears: Bus Manufacturers Embrace Electric Powertrains for Cleaner, Quieter Transportation2024-03-30

Shifting Gears: Bus Manufacturers Embrace Electric Powertrains for Cleaner, Quieter Transportation2024-03-30 -

Smart Shift: Bus Gearboxes Get an Upgrade with Advanced Transmission Technology2024-03-26

Smart Shift: Bus Gearboxes Get an Upgrade with Advanced Transmission Technology2024-03-26 -

Harnessing the Power of Hydrogen: Advancements in Fuel Cell Technology Revolutionize Bus Engines2024-03-22

Harnessing the Power of Hydrogen: Advancements in Fuel Cell Technology Revolutionize Bus Engines2024-03-22 -

Breakthrough in Bus Engine Efficiency: Researchers Develop Ultra-Low Emission Engine Technology2024-03-19

Breakthrough in Bus Engine Efficiency: Researchers Develop Ultra-Low Emission Engine Technology2024-03-19

.png)

.jpg)

.jpg)

.jpg)